(Robots, lawn mowers, drills, carts, shuttles, etc.)

The battery is the invisible engine of battery performance. In demanding systems, any failure impacts productivity and reputation.

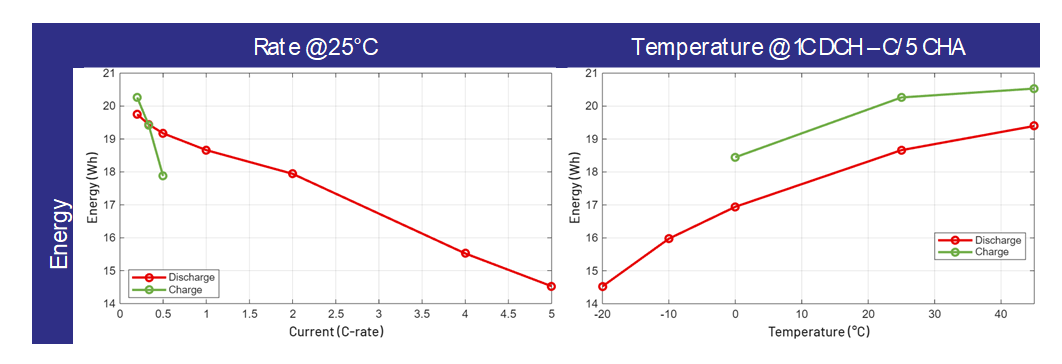

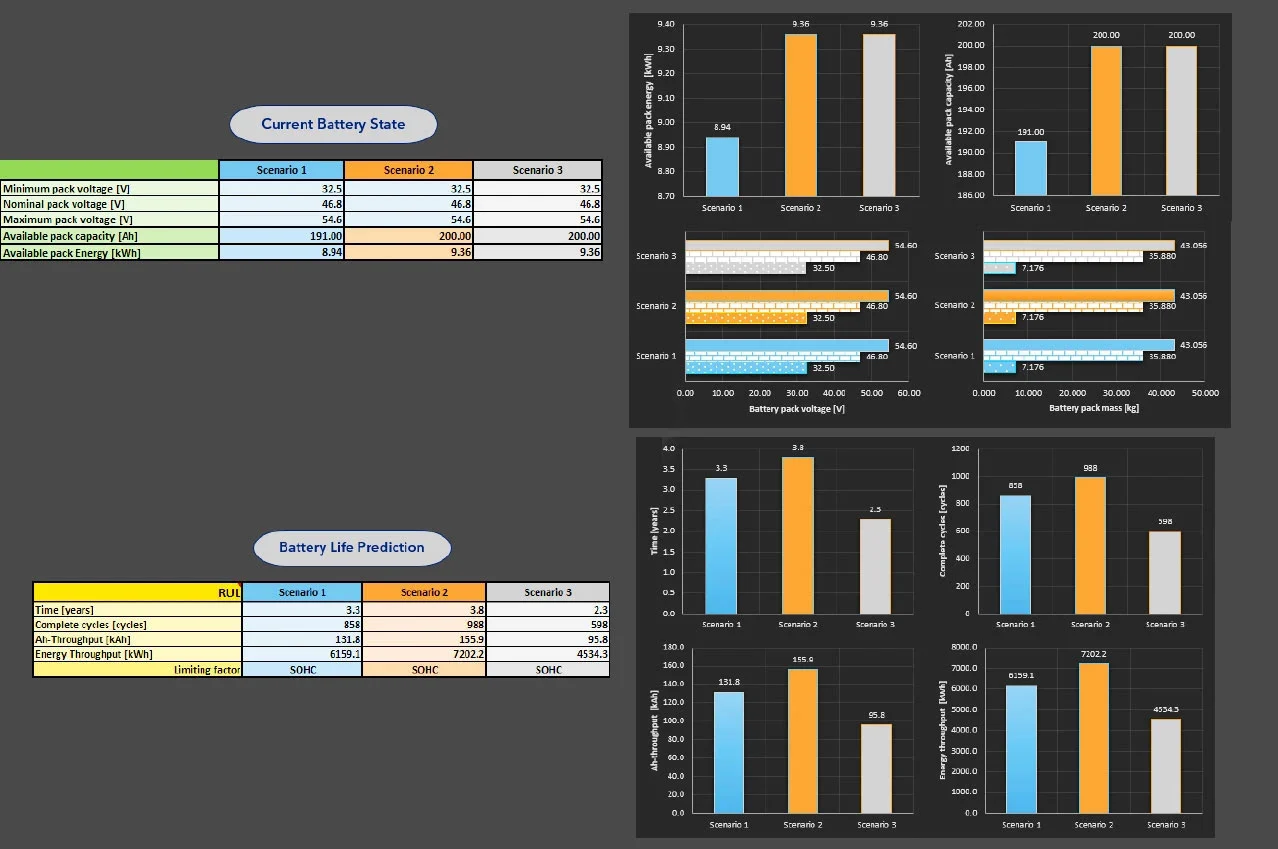

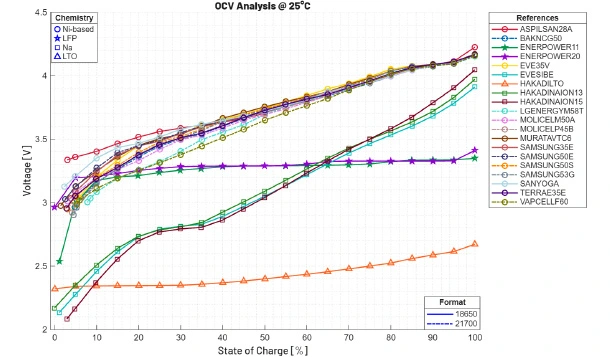

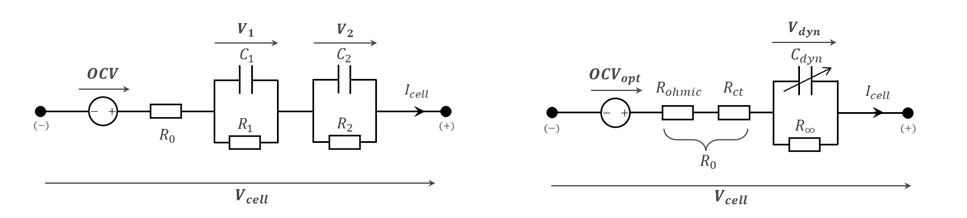

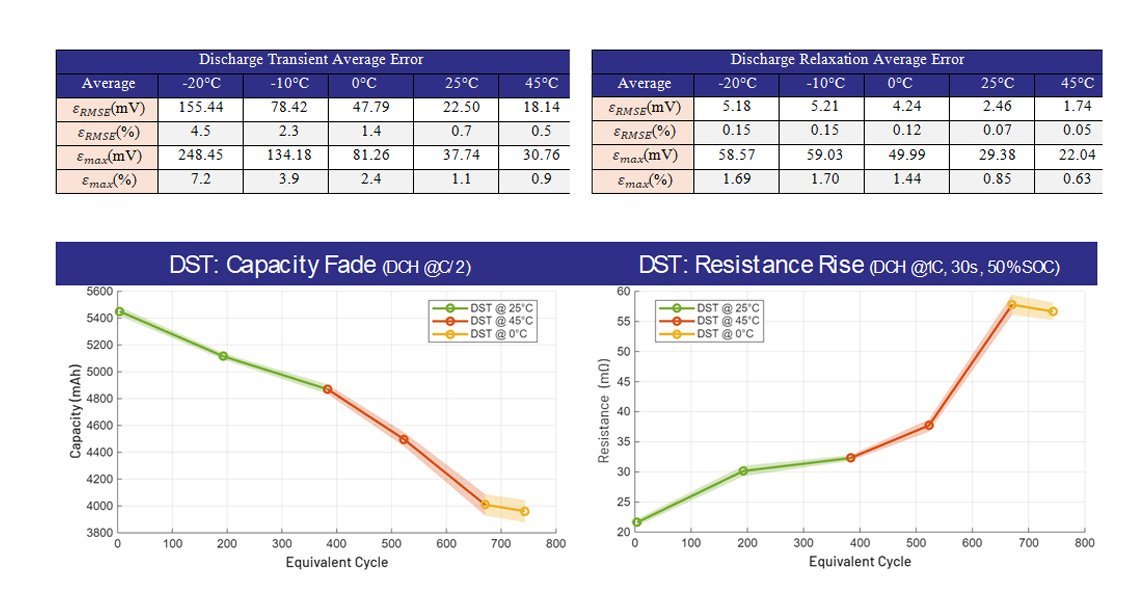

At kurybees, we combine battery performance and battery durability, through experimental and numerical approaches applied to industrial use cases.